How to Reinforce Concrete Block is one of the question that might be asked by construtors whose purposes are decoration or minor renovation. The reason is that many hobbyists are witnessing destruction of the concrete block walls they have made, even as a result of minor accidents. If the blocks are not sufficiently supported, it is inevitable to occur these accidents.

How to reinforce concrete block which can be used in almost any building and whose suitability for all types of residential, commercial and industrial applications has been proven? There is no need to be skeptical about the quality of a material whose durability and strength is widely accepted in the industry. Just know how to consolidate it.

The most important point during concrete block wall construction is tension. Mortar filled between the blocks creates a sufficiently strong holding effect. However, bending and stretching potential of the wall is quite low. Tensile strength of many wall products is close by this potential, whether made of concrete blocks or other materials. What you need to do to increase this rate can be listed as follows:

A large part of the concrete blocks consists of gaps. If these empty parts are not filled, the strength of the wall will not be too much. Concrete material containing small pebbles should be filled into the gaps. Mortar connecting the blocks and other concrete materials filling the gaps may seem strong enough for you. However, the stretching and bending strength of these materials are not adequate alone. So steel reinforcement is also significant.

The best material with tensile strength is steel. For example, half an inch reinforcing steel used in a housing project means approximately 18 tons of tensile strength. Thicker steel bars can be used to bear higher forces.

For the most positive results, use of reinforcing steels is ideal for connecting concrete blocks to the concrete floor of the wall. It will be sufficient to first set the steel bars on the ground with approximately 60 cm protrusion and then overlap them with the steel bars inside the wall.

It should be ensured that the steel bars passing through the hollows of the blocks are completely wrapped in pea gravel concrete. Therefore, the bars must be completely centered on the empty areas of the blocks. Absolutely, what purpose the wall was built should be taken into account. For example, if a retaining wall is being built, it may be necessary to position the steel closer to the surface of the wall that does not touch the ground. Hence, it may be helpful to seek advice from an engineer.

Built-in feet can be added to concrete block walls to make the wall stronger. Decorative engravings can also be made on the built-in feet. It is suitable for both strengthening the wall and giving it a different look.

We shared key points that can answer the question of how to reinforce a wall consisting of concrete blocks. We would like to remind you again, learning from an engineer is the best solution to know how and in which parts these items will be used.

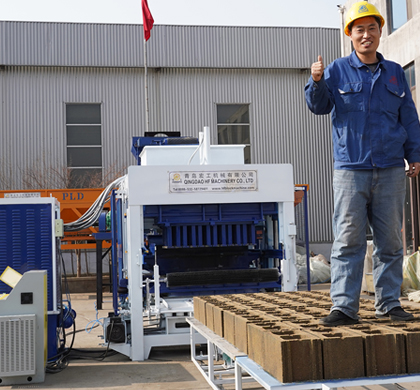

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.